Custom Wires and Mandrels for Medical Device Manufacturers

Specialties

-

Precision ground custom mandrels for catheter production.

Most efficient diameter range is from .010 - .200", which can include various tapers, steps and radii.

Typical materials include hardened stainless and tool steels (440C and M2), nitinol, and various 300 series stainless steels.

Tolerances of +/-.0001 or better can be achieved.

Prototype through small production levels.

-

Grinding of custom D Shaped Mandrels and grooved mandrels featuring various flats, complex and multi radii forms.

-

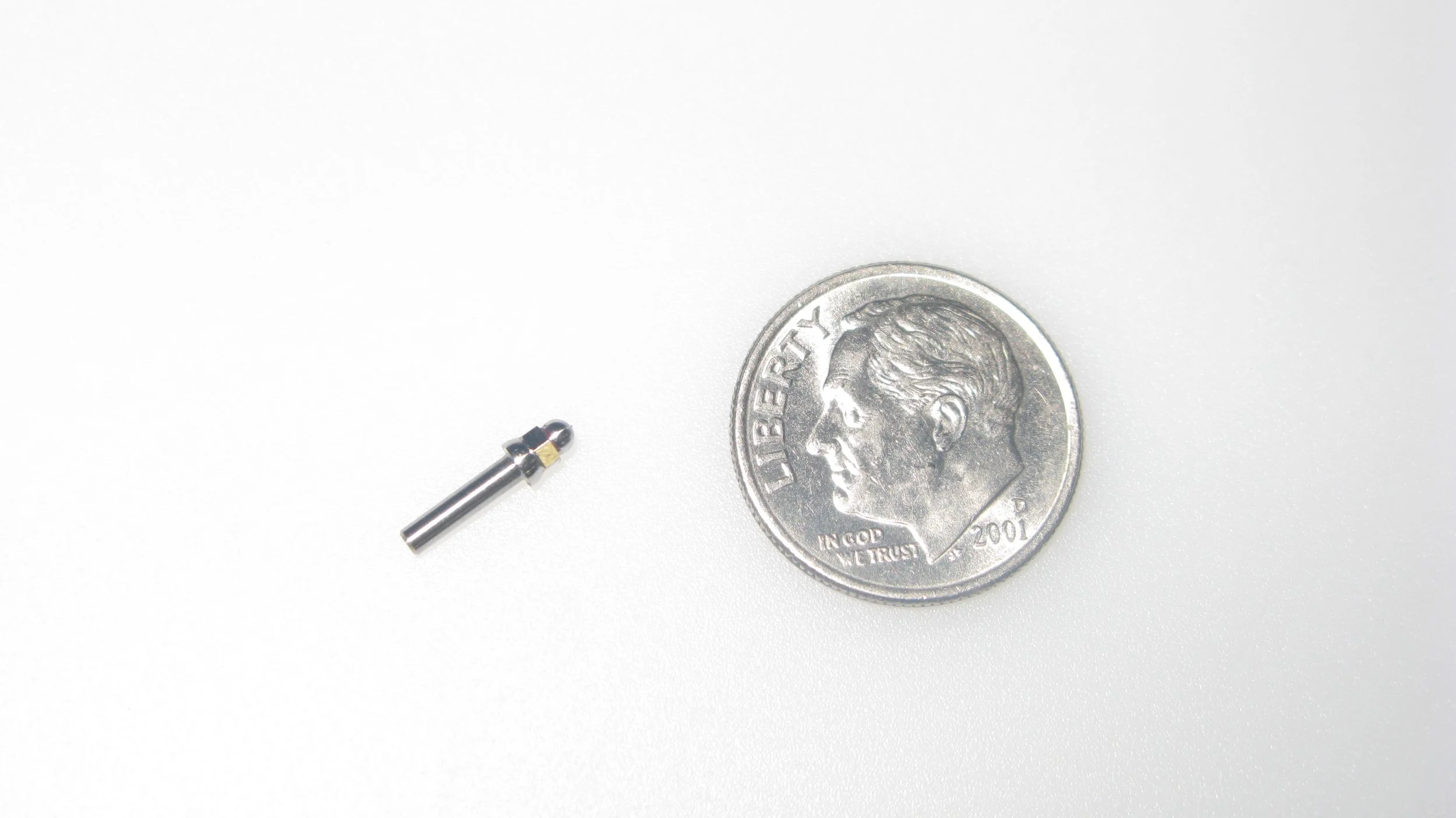

Precision ground custom core pins, ejector pins and guide pins in sizes down to .005

-

Precision ground core wires in 304 stainless, SLT and Nitinol.

Sizes range from .003 to .030".

We are most efficient in small prototype runs.

-

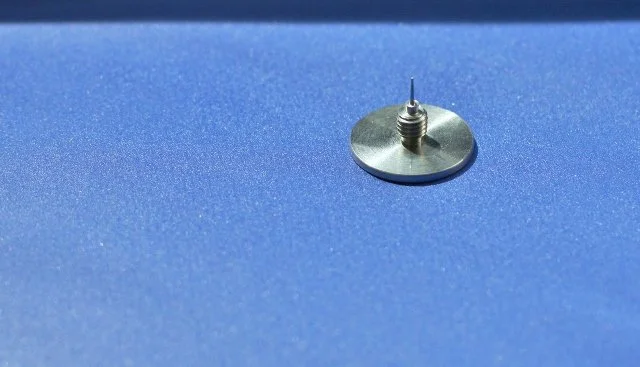

Custom ground hollow mandrels for catheter production.

Seam welded caps and hollow cores for heat sink.

These are typically made from hardened 17-7 stainless for improved cutting surface durability.

Various wall thickness from .005 - .030

Grinding Services

-

5 custom unversal CNC grinders, capable of ID / OD grinding.

-

Custom ground thread cores and custom threads with shrink.

-

Precision ground various straight wires, hypotubes and mandrels.

Value Added Service

-

We strategically partner with different trusted vendors to provide our customer finished parts with coatings of their choice, ensuring post coating dimensions are met.

-

In house custom fiber laser machine capable of precision located bands/rings of various width, part numbers, serialization and logos.

-

It is our goal to provide total satisfaction to our customers, saving time and eliminating headaches to provide you with a completed project.